60kV Electron Beam Welding Machines

60kV electron beam welding machines are typically used for the manufacture of small components including:

- Battery cans

- Medical components

- Aneroid capsules

- Latches

- Bellows

- Relays

- Electronic parts, including transducers

The low heat input means that sensitive internal electronics packages may be sealed in the device without harm.

Applications in the automotive industry include airbag inflators, vibration dampers, gearbox components, transmission parts, and turbocharger shaft wheel assemblies.

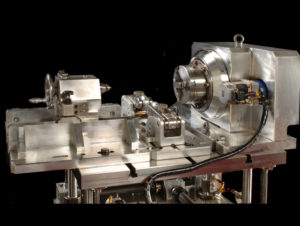

ECO Model

The ECO model has a modular, flexible design to enhance production capabilities. The ECO is ideal for welding small-to-medium-sized components, with a small footprint and high-efficiency. Find full details below or download the datasheet.

Specification

Standard Equipment

Advanced Features

Tooling Options

Gallery

| Standard chamber sizes include*

|

300x300x300m

355x355x355mm 450x450x450mm 610x610x610mm |

| 60kV beam power

|

Standard up to 4kW (60mA at 60kV)

Optional up to 6kW (100mA at 60kV) |

| Gun vacuum | 10-5 mbar range |

| Chamber vacuum | 10-4 mbar range |

| Chamber pump down time (to 10-4 mbar) | 30-120 seconds** |

| Weld depth at 760mm per minute (at 4kW) | Stainless steel = 15mm |

*Other sizes are available upon request

**Dependent on pump specification, chamber size and customer requirements

- Air-conditioned electrical cabinet

- Beam deflection patterns

- CCTV HDMI viewing system

- Chamber viewing window

- Directly heated cathode

- eWon ethernet hub for remote diagnostics

- External rotary manipulator

- Filament alignment jig

- Function generator for application of welding patterns

- High-quality HDMI camera, with adjustable cross hairs and video capability

- Industrial PLC

- Manual gun-slide ±32mm

- Mechanical and diffusion pumps for high-vacuum operation

- PC-based HMI, with recipe storage and data logging

- Separately pumped gun column (turbo-molecular)

- Automatic joint finder and imaging using back scattered electrons

- Bino optics

- CNC control

- Dry vacuum pumps

- Larger, motorised gun-slides (PLC controlled)

- Recirculating water chiller

- Special beam functions, including beam splitting

- Automatic focus and alignment

- Chamber extensions

- Custom tooling

- Indexing carousel

- Internal rotary manipulator and tilt

- Tailstock

- XY table

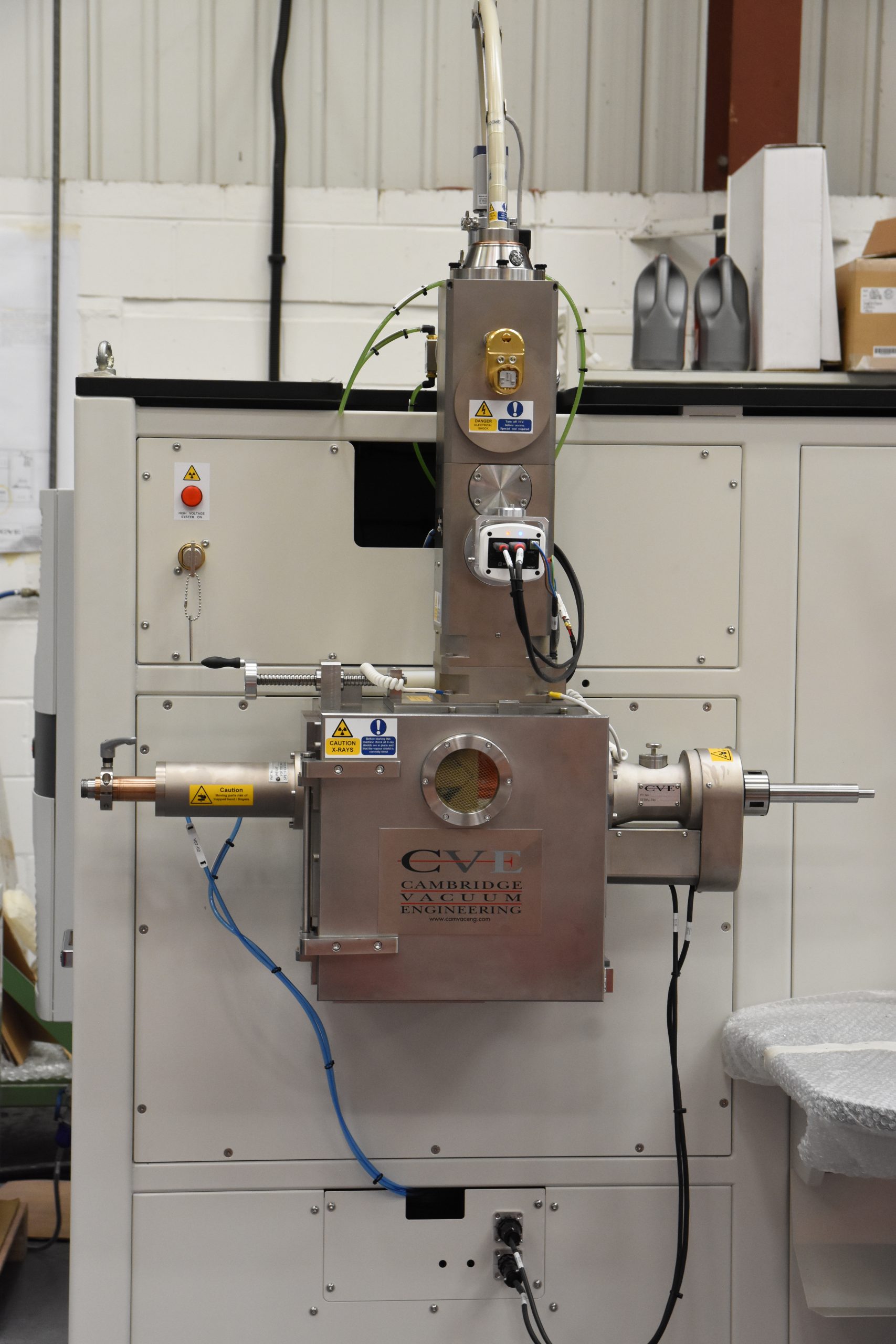

ECO Model

60kV Gun Column

HMI with CNC Control

Internal Carousel

Rotary Table

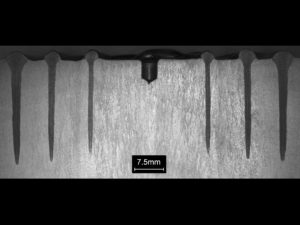

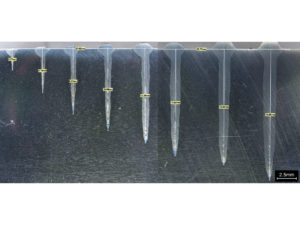

60kV Welds

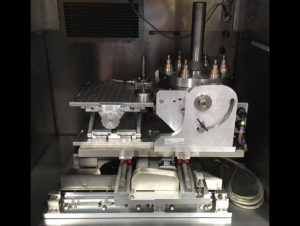

CW Model

The CW model has a modular, flexible design to enhance production capabilities. The CW is ideal for the welding of medium-sized components and is suitable for thermally conductive materials. Find full details below or download the datasheet.

Specification

Standard Equipment

Advanced Features

Tooling Options

Gallery

| Standard chamber sizes include

Other sizes are available upon request

|

450x450x450mm

610x610x610mm 1,000x750x800mm 1,100×1,100×1,100mm 1,400×1,000×1,250mm 2,250×1,250×1,400mm |

| 60kV beam power | Standard up to 6kW (100mA at 60kV) Optional up to 15kW (250mA at 60kV) |

| Gun vacuum | 10-5 mbar range |

| Chamber vacuum | 10-4 mbar range |

| Chamber pump down time (to 10-4 mbar) | Dependent on chamber volume, pump specification and customer requirements |

- Air-conditioned electrical cabinet

- Beam deflection patterns

- Chamber viewing window

- Directly heated cathode

- eWon ethernet hub for remote diagnostics

- Filament alignment jig

- Function generator for application of welding patterns

- High-quality HDMI camera, with adjustable cross hairs and video capability

- Industrial PLC

- Manual gun-slide ±32mm

- Mechanical and diffusion pumps for high-vacuum operation

- PC-based HMI, with recipe storage and data logging

- Separately pumped gun column (turbo-molecular)

- Automatic focus and alignment

- Automatic joint finder and imaging using back scattered electrons

- CNC control

- Dry vacuum pumps

- Internal rotary tilt carousel

- Mylar film protector

- Recirculating water chiller

- Special beam functions, including beam splitting

- Chamber extensions

- Custom tooling

- External rotary manipulator

- Indexing carousel

- Internal rotary manipulator, tilt, and Z lift

- Motorised gun-slide

- Motorised run-out platform

- Tailstock

- XY table

CW Model

Heavy-duty gun column and HDMI camera

HMI with CNC Control

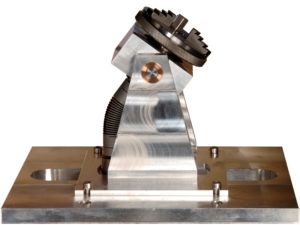

Custom tooling table with z-lift

Manual scissor lift, indexing carousel, and beam probe

60kV welds