Strip and Batch Electron Beam Welding Machines

Continuous strip and batch welders are suitable for large production batches and for joining two or three dissimilar metals.

A batch or continuous strip machine will allow you to weld continuous strips, rather than individual components – reducing labour and material costs.

Typical components include:

- Metal strips

- Sensors

- Relays

This process is used in many industries.

Batch Model

The batch model has high-efficiency and is suitable for bi-metallic or tri-metallic welding. Find full details below or download the datasheet.

Specification

Standard Equipment

Advanced Features and Tooling Options

Gallery

| Maximum number of strips weldable | 3 |

| Strip dimensions*

Length Combined width Thickness |

250mm170mm

3mm |

| Cycle time/weld speed** | 30 seconds + weld process time |

| 60kV beam power

|

Standard 10kW (167mA at 60kV)

Optional 15kW (250mA at 60kV) |

| Gun vacuum | 10-5 mbar range |

| Chamber vacuum | 10-2 mbar range |

*Other sizes are available on request

**Time as a guide only – faster speeds may be possible

- Automatic filament heating

- Beam deflection patterns and function generator

- Directly heated cathode with high-intensity beam for low distortion

- Ethernet hub for remote diagnostics

- High-quality HDMI camera and vision systems

- Industrial PLC with PC-based HMI for recipe storage and data logging

- Interchangeable PTFE seals accommodating various strip sizes (continuous strip system)

- Multiple vacuum chambers (continuous strip system)

- Separately pumped gun column (a second gun and power supply used on the continuous strip system)

- Strip alignment system to ensure parts remain in contact (continuous strip system)

- Quick release tooling with repeatable positioning (batch system)

- X-table for part manipulation (batch system)

- Automatic beam alignment

- Automatic joint finding option for up to two joints simultaneously

- High-speed deflection coil option for split beam welding

- Light guard protection of the loading area

- Manually operated jig for rapid, accurate clamping of parts (batch system)

- MES and industry 4.0 compatibility

Batch Model

Tooling

Tooling

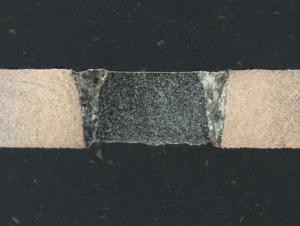

Example Part and Weld

Continuous Strip Model

The batch model has high-efficiency and is suitable for bi-metallic or tri-metallic welding. Find full details below or download the datasheet.

Specification

Standard Equipment

Advanced Features and Tooling Options

Gallery

| Maximum number of strips weldable | 3 |

| Strip dimensions*

Length Combined width Thickness |

n/a170mm

3mm |

| Cycle time/weld speed** | 0.3mm/s |

| 60kV beam power | Standard 15kW |

| Gun vacuum | 10-5 mbar range |

| Chamber vacuum | 10-2 mbar range |

*Other sizes are available on request

**Time as a guide only – faster speeds may be possible

- Automatic filament heating

- Beam deflection patterns and function generator

- Directly heated cathode with high-intensity beam for low distortion

- Ethernet hub for remote diagnostics

- High-quality HDMI camera and vision systems

- Industrial PLC with PC-based HMI for recipe storage and data logging

- Interchangeable PTFE seals accommodating various strip sizes (continuous strip system)

- Multiple vacuum chambers (continuous strip system)

- Separately pumped gun column (a second gun and power supply used on the continuous strip system)

- Strip alignment system to ensure parts remain in contact (continuous strip system)

- Quick release tooling with repeatable positioning (batch system)

- X-table for part manipulation (batch system)

- Automatic beam alignment

- Automatic joint finding option for up to two joints simultaneously

- High-speed deflection coil option for split beam welding

- Light guard protection of the loading area

- Manually operated jig for rapid, accurate clamping of parts (batch system)

- MES and industry 4.0 compatibility

Continuous Strip System

Strip Alignment

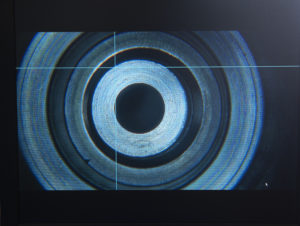

HMI with cross-hairs

Weld cross-section